Sharp AR-C240P Specifications

Browse online or download Specifications for Copiers Sharp AR-C240P. Sharp AR-C240P Specifications User Manual

- Page / 196

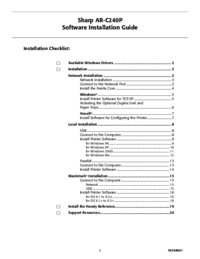

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

- AR -C 240P 1

- CONTENTS 3

- 1. CONFIGURATIONS 6

- 1.1 System Configuration 6

- 1.2 Printer Configuration 7

- 1.3 Supplies and Consumables 8

- Option Configuration 9

- 1.4 Specifications 10

- 2. OPERATION DESCRIPTION 12

- 2.1 Main Board (TIG PWB) 13

- 2.3 Power Units 16

- Disconnect 17

- [Maintenance Tools] 18

- Table 2-1 Maintenance Tools 18

- 2.2 Parts layout 19

- For 600dpi 20

- [Printer Unit-1/2] 21

- Figure 2-3 21

- [Printer Unit-2/2] 22

- Figure 2-4 22

- [Cassette Guide Assy (L),(R)] 23

- Figure 2-5 23

- [Duplex Unit] 24

- Figure 2-6 24

- 2.3 Replacing Parts 25

- 2.3.1 Top Cover 27

- (1) Open the Top Cover assy 27

- Figure 2-3-1 Top Cover 27

- 2.3.6 Eject Guide Assy 32

- (1) Remove the cassette 1 34

- 2.3.11 Face-Up Tray 37

- Figure 2-3-11 Face-Up Tray 37

- 2.3.15 Drum Contact Assys 41

- Stage height adjustment jig 43

- Top surface 43

- 2.3.20 Main Cooling Fan 46

- Connectors 47

- 2.3.22 Duplex Guide Assy 48

- Main chassis 52

- 2.3.27 Entrance Sensor PWB 53

- 2.3.30 Exit Sensor Assy 56

- 2.3.42 Fuser Unit 68

- (1) Open the top cover 1 68

- Figure 2-3-42 Fuser Unit 68

- 2.3.44 Duplex Unit 70

- Figure 2-3-44 Duplex Unit 70

- 3. ADJUSTMENT 76

- 3.0 System Maintenance MENU 76

- Maintenance Menu 78

- SWITCH SCAN 80

- MOTOR & CLUTCH TEST 84

- BLACK - ID MOTOR 84

- Figure 3-3 85

- Table 3-2 85

- TEST PATTERN 86

- Pattern 5 Pattern 6 88

- Pattern 7 88

- MTR=*.**KV CTR=*.**KV 89

- P=*** T=*** U=***[###] 89

- H=***% L=***[###] 89

- KTR=*.**KV YTR=*.**KV 89

- NV-RAM INITIAL 90

- TOTAL SHEETS FEED 91

- BLACK IMPRESSIONS 91

- YELLOW IMPRESSIONS 91

- MAGENTA IMPRESSIONS 91

- CYAN IMPRESSIONS 91

- 3.1.2.9 Panel display details 92

- Panel display 92

- Details of jam error display 96

- Value Check 101

- Measurement point 104

- 2-Character correction value 108

- Code content Barcode 108

- 5. TROUBLESHOOTING PROCEDURES 111

- 5.5 Troubleshooting Procedure 112

- Back-up roller thermister 128

- Heat roller thermister 128

- DIAGNOSTIC MODE 139

- XX.XX.XX 139

- Charge Roller 144

- Developing Roller 144

- Toner Supply Roller 144

- 5.6 Fuse check 145

- 6. CONNECTION DIAGRAM 146

- 6.1 Resistance Checks 146

- Feeder Motor 148

- Duplex Motor 148

- 6.2 Program/Font ROM Layouts 150

- (2) Main Controller PWB 152

- (6) N71 PWB 154

- Item Description 156

- INPUT. PRIME 157

- ACKNOWLEDGE 157

- 1. Parts Replacement 160

- APPENDIX C ERROR MESSAGES 165

- 1. Error messages 165

- 5. Other Warnings 177

- PARTS GUIDE 179

- (1) Main Assembly 1/3 181

- (1) Main Assembly 2/3 182

- (1) Main Assembly 3/3 183

- (2) Top Cover Assembly 185

- (2) Top Cover Assembly 186

- (3) Printer Unit Chassis 1/2 187

- (3) Printer Unit Chassis 2/2 188

- (3) Printer Unit Chassis 189

- (4) Paper Tray Guide 191

- (4)Paper Tray Guide 192

- (5)Duplex Unit 193

- (5) Duplex Unit 194

- ALL RIGHTS RESERVED 196

Summary of Contents

P arts marked with “ ” are important for maintaining the safety of the set. B e sure to replace these parts withspecified ones for maintaining the s

10 / 1.4 Specifications(1) External Dimensions Height: 430mm Width: 430mm Length: 620mm(2) Weight 42 kg(3)

100 / 3.2.5 Recovery Flash ROM data on TIG boardA 4MB Flash ROM that enables a user to register an arbitrary file is insta

101 / 3.4 Paper Thickness Detection Sensitivity Adjustment and Media Thickness DetectionValue CheckOutline:The sensitivit

102 / 3.4.2 Setting3.4.2.1 Menu Setting(1) Power on the PC.(2) Create an arbitrary folder, and copy the two files Adjust

103 / (7) Setting screen appears. Select (mark) LPT1 or USB on the Printer Port menu. Press OK.Note:Do not change setti

104 / 3.4.2.2 Media Setting(1) The media thickness input screen is displayed.Prepare four sensitivity adjustment transpare

105 / 3.4.2.3 Sensitivity Adjustment(1) With the press of OK on the ADJUSTMM screen, sensitivity adjustment is performed.

106 / 3.4.2.4 Actions for NG Sensitivity AdjustmentWhen a CSV format file stored automatically in sensitivity adjustment i

107/ 3.4.3 Inputting the density of the calibration chip for density detectionWrite the calibration target adjustment valu

108 / (12) Enter the correction value marked on the barcode label on the shutter into the Input fieldand press OK (the Mun

109 / 3.4.4 Electronic Serial Number Input[Outline]The 22-character electronic serial number (E-S/N) that has been marked

11 / (12) Temperatures and Relative HumiditiesTemperatureTemperature ConditionTemperature( F) Temperature( C) RemarkOpe

110 / 4. REGULAR MAINTENANCE4.1 Parts Replaced RegularlyUsers are recommended to replace parts periodically according to t

111 / 5. TROUBLESHOOTING PROCEDURES5.1 Precautions before troubleshooting(1) Confirm the basic inspection items described

112 / 5.4 Preparing for Troubleshooting(1) Operator panel displayProblems that occur with the printer are indicated in the

113 / 5.5.1 LCD message listWhen the printer detects a non-recoverable error, the following service call error is displaye

114 / Table 5-1-1 Operator Alarm (2/6)Message Cause Error Description SolutionsService Call042: Error~044: ErrorService C

115 / Table 5-1-1 Operator Alarm (3/6)Message Cause Error Description SolutionsService Call110: Error~116: Error110: Enve

116 / Table 5-1-1 Operator Alarm (4/6)Message Cause Error Description SolutionsService Call160: Y Toner161: M Toner162: C

117 / Table 5-1-1 Operator Alarm (5/6)Message Cause Error Description SolutionsReset belt330: Belt errorReset drum330~343

118 / Table 5-1-1 Operator Alarm (6/6)Message Cause Error Description SolutionsOpen top cover389: Paper jamCheck MP tray3

119 / 5.5.2 Preparing for troubleshooting(1) Operator panel displayProblems that are generated in this device are indicate

12 /2. OPERATION DESCRIPTIONThe C7500/C7300 of printers, tandem color electrophotographic page printers, adopt technol

120 / 1 The printer does not function properly after power ON.• Turn the power OFF then ON.• Is

121 / 2-1 Feed jam (1st tray)• Do feed jams occur right after power ON?• Yes Is the jam at the entrance cassette sensor or

122 / 2-2 Feed jam (multipurpose tray)• Do feed jams occur right after power ON?• Yes Is the jam at the entrance cassette

123 / 2-3 Path jam• Do path jams occur right after power ON?• Yes Is the jam at the entrance belt sensor?Yes Remove the ja

124 / 2-4 Exit jam• Do exit jams occur right after power ON?• Yes Is the jam at the paper exit sensor?• Yes Remove the jam

125 / 2-5 Duplex jam• Do path jams occur right after power ON?• Yes Is there paper in the duplex print unit?Yes Remove the

126 / 3 Paper size error• Is paper of regulated size being used?No Use paper of regulated size.▼• Yes Is a jam detected by

127 / 4 Up/Down movement error of the image drum unit (ID)• Turn the printer OFF, then turn it ON after a few seconds.• Ar

128 / 5 Fuser unit error• Do fuser errors occur right after power ON?(A)• Yes Is the heat roller thermister disconnected o

129 / 5 Motor fan error• Does the low-voltage power fan rotate at power ON?• No Is 34V output to fuse F7 on the engine boar

13 / 2.1 Main Board (TIG PWB)Figure 2-2 provides the block diagram of the main control board (TIG PWB).Figure 2-23PU-C

130 / Abnormal Image Flowchart No.The entire image is faint or the color is irregular. (Figure 5.2- A ) 1The white portion

131 / 1 An image is generally faint or the color is irregular. (Fig 5-2 A )• Is the amount of toner low? (Is [Toner Low] i

132 / 2 Dirty Background. (Fig. 5-2 B )• Was the image drum exposed to external light for a long time?Yes Replace the I/D

133 / 3 White page (Fig 5-2 C )• Is the LED head assembly connected properly to the connection board (Y73 PWB) or engine

134 / 4 Solid lines or streaks appear in the vertical direction. (Black lines, color lines / black streaks, colorstreaks)

135 / 5 Thick white lines / streaks or blurred color lines / streaks appear in the vertical direction (Fig. 5-2 F )• Is t

136 / 6 Poor Fusing (Ink spreads or peels when touched with fingers)• Is regulated paper being used?NO Use regulated paper

137 / 7 Consistent abnormality (Figure 5.2- E )Note:The life counter for the I/D unit, fuser unit, and belt cassette unit

138 / 8 Color detaches.• Is the LED head dirty?YES Clean the LED head.▼• NO Is the LED head assembly connected to the conn

139 / 9 Color irregularity• [Toner Low] is displayed.YES Refill toner. Did the printer recover?YES End.▼• NO Perform the c

14/ (1) CPUThe CPU is PowerPC750CXe, a 64-bit bus RISC processor, which inputs an 100-MHz CLK(= BUS CLK), and operates at

140 / (A)▼• NO [NG CALIBRATION LEFT /RIGHT] display.• YES Is the color irregularity sensor cover dirty?YES: Faulty cleanin

141 / (B)• [Yellow/Magenta/Cyan Left/Right/Horizontal] display▼• YES Replace the belt unit. Did the printer recover?YES En

142 / 0 Color irregularity compared with the original• Is the LED head lens dirty?YES Clean the LED head lens.▼• NO Is the

143 / A Paper thickness error (Err Code 323, 324)• Is the sensor connector connected?NO Connect the connecter.▼• YES Is the

144 / Figure 5.3GroundCharge RollerDeveloping RollerToner Supply Roller

145 / 5.6 Fuse checkWhen it is occured bellow errors, check these fuses on Print Engine Controller PWB (K7N-PWB).Table 5-

146 / 6. CONNECTION DIAGRAM6.1 Resistance ChecksUnit Circuit Diagram Illustration ResistanceBetween pins 1 and 2: 7.9.Bet

147 / Unit Circuit Diagram Illustration ResistanceBetween pins 1 and 2: 8.6.Between pins 3 and 4: 8.6.Between pins 1 and

148 / RedBrownYellowBlueM1234Unit Circuit Diagram Illustration ResistanceBetween pins 1 and 2: 7.9.Between pins 3 and 4:

149 / cdefab1. Upper roller side2. Backup roller sideUnit Circuit Diagram Illustration Resistance1. Upper Roller SideBetw

15/ Figure 2-3The engine control block (PU) is controlled by the engine controller board (K71 PWB) whichconsists of a CPU (MSM66Q577), general LSI

150 / 6.2 Program/Font ROM Layouts(1) Print Engine Controller PWBa) (K7N PWB : 600dpi)JODENFEEDFSENSPARTTEMPRSNSREGDUPLEXP

151 /

152 / (2) Main Controller PWBPUIFFAN3848411185168B85168ADIMM84285168168168841853 ~DIMM sockets(SDRAM DIMM (64MB ‘512MB) p)

153 / POWERSTUCKCPOW2MPOW2YPOW2TNRSNSCTNRSNSMTNRSNSYOPTNKPOW2TNRSNSKPANEL(4) Duplex Control PWB (V71--N PWB)FU1FSNSMAINMOT

154 / (6) N71 PWBJODEN(7) Entrance Sensor PWB (R71 PWB)HUMWRSNSINSNS1INSNS2TNRFSNS(8) Paper Size Sensing PWB (PXC PWB)CN11

155 / (9) High voltage power supply PWB(10) Low voltage power supply PWBCN1CN2CN2CN1CN4-2(CN6-2)CN4-1(CN6-1)CN5ACINCN3F2F1

156 / APPENDIX A INTERFACE SPECIFICATIONS1. Parallel Interface Specifications1.1 Parallel Interface Item DescriptionMode C

157 / 1.4 Timing ChartsCompatible modea) Data receiving timingPARALLEL DATA(DATA BITs 1 to 8)nStrobenAckBUSY 0.5 ∝s min.0

158 / 1.5 Parallel I/F SignalsTable 8-1 shows interface signal names and pin numbers.Table 8-1 SignalsPin No. Signal Name

159 / 2. Universal Serial Bus (USB) Interface Specifications2.1 USB Interface(1) Basic specificationsConforms to USB speci

16/ Output Voltage Use for+5 V LED head+5 V Logic circuit power supply, PU CPU+34 V Motor, drive voltage and power su

160 / APPENDIX B 2ND/3RD TRAY MAINTENANCE1. Parts Replacement1.1 Cover Idle Roller Assy(1) Unscrew the four screws 1 to re

161 / 342111121.2 PCB(1) Unscrew the four screws 1 to remove the plate cover PCB 2.(2) Remove the connectors (at seven plac

162 / 3333234009711ECBAEF8DD3111151.3 Feeder Drive Assy(1) Remove the four screws 1, six screws 2 and the eight screws 3.(

163 / 123485672. 2nd/3rd Tray PARTS LIST

165/ APPENDIX C ERROR MESSAGES1. Error messages(Caution) * : Raise in the factory mode only.** : Not raise in the

166 / LED AttenBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkLCD Messages

167 / LED AttenBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkLCD Messages CHECK DUP

168 / LED AttenBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkLCD Messages INST

169 / LED AttenBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkLCD Messages REMOVE THE PAPER450:

17 / (2) Do not disassemble the printer so long as it operates properly.(3) Minimize the disassembly. Do not detach parts

170 / LED AttenBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkOFFLCD Messages CHANGE

171 / LED AttenBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkBlinkLCD Messages CHECK PAPER CASSETTE520:TRAY1 LIFT UP ERRORCH

172 / LED AttenVariesVariesVariesLightLightLightLightLightLightLightLightLightLightLCD Messages _COLOR ADJUSTING_DENSITY AD

173 / LED AttenLightLightLightLightLightLightLightLightLightLightLightLightLightLightLightLightLightLightLCD Messages DENSI

174 / LED AttenLightLightLightVariesVariesLCD Messages REGISTRATION SENSOR ERROR3REGISTRATION SENSOR ERROR4REGISTRATION SE

175 / 3. Warning messages : Usage, MediaLED AttenVariesLightLightLightLightLightLightLightLightLightLightLightVariesV

176 / 4. Warning messages : Job AccountLED AttenVariesVariesLightLightLightLCD Messages FILE ACCESSINGCANCELLING(USER

177/ 5. Other Warnings(Caution) * : Raise in the factory mode only.LED AttenLightLightLightLightLightOFFLCD Messages

178 / In case

q PARTS GUIDECONTENTSBecause parts marked with "!" is indispensable for the machine safety maintenance and poeration, it mustBe replaced

18 / [Maintenance Tools]Table 2-1 lists tools necessary to replace the printed circuit boards and the units.Table 2-1 Main

181 / Figure 7-1-1/3353739, 40, 41, 4242234376203018141121126AAB82829192125122829283332931BA292928AB2929282829292329293229

182 / ABABCCC132923C291024242323Figure 7-1-2/3(1) Main Assembly 2/3

183 / Figure 7-1-3/34935504451504346474836(1) Main Assembly 3/3

Table 7-1No. Part Number Description Comment1 0ZZ40864601// Front Cover Assy2 0ZZ41042501// Front Cover Inner Baffle3 0ZZ40866701// Cassette Assy4 0ZZ

185 / Figure 7-223324242332424233242423324241514191414415611(600dpi)8 (600dpi) 7 (600dpi) 9 (600dpi) 10 (600dpi)171821 2

(2) Top Cover Assembly No. Part Number Description Comment1 0ZZ40859702// Top Cover2 0ZZ42460901// LED Assy (600dpi) Kit3 0ZZ42216201// LED Assy Spri

187 / Figure 7-3-1/2AA3161918605617244721252681371214282327110911511530312922222415054515857555159515151515151514951515151

188/ 31334440414839364345373438323547474747474747474747474747474747475253Figure 7-3-2/2(3) Printer Unit Chassis 2/2

(3) Printer Unit Chassis No. Part Number Description Comments1 0ZZ41189701// Drum contact Assy2 0ZZ40844306// Registration Roller Assy (A)3 0ZZ4084430

19 / 2.2 Parts layoutFigure 2-1AABBAAB

(3) Printer Unit Chassis No. Part Number Description Comments41 0ZZ41862901// Power-Unit AC-DC-switching(115V) 43 0ZZ42046801// Power-Unit (high-volta

191 / ABBACC’CC’16151162116121419161116514321919202020202020191919191919Figure 7-4(4) Paper Tray Guide

No. Part Number Description Comments1 0ZZ40839801// Main Feed Assy2 0ZZ40371302// Feed Roller3 0ZZ40313202// Nudger Roller4 0ZZ40325401// Main Feeder

193 / ABDCABCDEEFGGF23363344454144444444Figure 7-5(5)Duplex Unit

No. Part Number Description Comments1 0ZZ41946501// Duplex Transport Assy SPC6 0ZZ50133401// Duplex Unit AR-C20ADU(5) Dup

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, p

20 / [Top Cover Assy]Figure 2-2 For 600dpi

21 / [Printer Unit-1/2]Figure 2-3AA

22 / [Printer Unit-2/2]Figure 2-4

23 / [Cassette Guide Assy (L),(R)]Figure 2-5ABBACC’CC’

24 / [Duplex Unit]ABDCABCDEEFGGFFigure 2-6

25 / 2.3 Replacing PartsThis section describes how to replace the parts and assemblies shown in the following disassem-blin

26 / ABoard Assy-CUPCB Assy_TIGBoard Memory 64MBBoard CRFCU Board AssyBoard_TIG0ZZ41964009//Board Assy.-CU(711)0ZZ41278601/

27/ 21112.3.1 Top Cover(1) Open the Top Cover assy.(2) Remove the nine screws 1 to detach the top cover 2.Figure 2-3-1 Top

28 / 1343422.3.2 LED Head / LED Spring / Post-Guide(1) Open the top cover 1.(2) Remove the three cables, and unhook the LED

29 / 2.3.3 Top Cover Unit(1) Remove the top cover (see section 2.3.1).(2) Remove the rear cover (see section 2.3.10).(3) Re

3 / CONTENTS1. CONFIGURATIONS ...

30 / 9B3376A51004282.3.4 Control Panel Assy/ Control Panel Bezel/ LED Control PWB/ Toner Sensors/ Stacker Full Sensor/Contr

31 / 3112442.3.5 Top Cover Handle/ Top Cover Latch/ Top Cover Latch Spring(1) Remove the two screws 1 to detach the top cov

32 / 11122.3.6 Eject Guide Assy(1) Remove the five screws 1 to detach the eject guide Assy 2.Figure 2-3-6 Eject Guide Assy

33 / 1232.3.7 Cassette Assy/ Front Cover Assy/ Front Cover Inner Baffle(1) Detach the cassette Assy 1.(2) Open the front c

34 / 1322.3.8 Retard Pad Assy/ Retard Pad Assy Spring(1) Remove the cassette 1.(2) Detach the retard pad Assy 2 (at the sam

35 / 122.3.9 Feed Roller and Nudger Roller(1) Remove the cassette.(2) Unlatch and demount the feed roller 1.(3) Unlatch an

36 / 213112.3.10 Rear Cover(1) Remove the left side cover (see section 2.3.12).(2) Remove the four screws 1 to detach the

37 / 12.3.11 Face-Up Tray(1) Open the face-up tray 1 in the arrow direction, and disengage it at two places to detach it.F

38 / 44145322.3.12 Left Side Cover(1) Open the top cover 1.(2) Open the front cover 2 and undo the screw 3.(3) Remove the

39 / 1235442.3.13 Right Side Cover(1) Open the top cover 1.(2) Open the front cover 2 and undo the screw 3.(2) Remove the

4/ 2.3.43 Belt Unit ...

40 / 2.3.14 Multipurpose Tray Assy/ Multipurpose Tray Cover Assy/ Links/ Multipurpose Tray Top Cover/Multipurpose Tray Dri

41 / 12.3.15 Drum Contact Assys(1) Insert a flatblade screwdriver between the printer case and the drum contact Assy 1 to

42 / 2.3.16 Media Thickness Sensor Assy(1) Detach the Cover Seal Sensor 1 and the Thickness Sensor Connector 2.(2) Rem

43 / Stage height adjustment jigTop surfaceTop surfaceStage height adjustment jig133465122.3.17 Registration Roller Assy (

44 / 1211Figure 2-3-18 Registration Roller Assy (B)2.3.18 Registration Roller Assy (B)(1) Remove the cassette Assy.(2) Op

45 / 62521453Figure 2-3-19 Registration Clutch and Registration Motor Assy2.3.19 Registration Clutch and Registration Mot

46 / 132OutletFigure 2-3-20 Main Cooling Fan2.3.20 Main Cooling Fan(1) Unhook the connector 1, and remove the screw 2 and

47 / 1123ConnectorsFigure 2-3-21 Color Registration Sensor Assy2.3.21 Color Registration Sensor Assy(1) Remove the two s

48 / 1Main chassis (rear)2.3.22 Duplex Guide Assy(1) Unlatch and demount the duplex guide 1.Figure 2-3-22 Duplex Guide As

49 / Outlet12155553346872.3.23 Electrical Chassis Cooling Fan(1) Unscrew the four screws 1 to remove the plate A 2.(2) Uns

5/ 6. CONNECTION DIAGRAM ... 1466.1 Resista

50 / 112Figure 2-3-24 Printer Engine Controller PWB2.3.24 Printer Engine Controller PWB(1) Remove the right side cover (s

51 / 12345343889436674Figure 2-3-25 Pinter Unit Chassis2.3.25 Printer Unit Chassis(1) Unscrew the two screws 1 and remove

52 / 1Main chassisFigure 2-3-26 Entrance Cassette Sensor Actuator2.3.26 Entrance Cassette Sensor Actuator(1) Remove the p

53 / 12Figure 2-3-27 Entrance Sensor PWB2.3.27 Entrance Sensor PWB(1) Remove the registration roller Assy (B) (see sectio

54 / 2132.3.28 Entrance MT Sensor Actuator / Entrance Belt Sensor Actuator / Entrance Waste Chassis SensorActuator(1) Remo

55 / BA78906124352.3.29 Fuser Exit Roller(1) Unscrew the two screws 1 to remove the duplex gate solenoid Assy 2.(2) Unscre

56 / 122.3.30 Exit Sensor Assy(1) Remove the fuser exit roller (see section 2.3.29).(2) Remove the screw 1 and connector t

57 / 3122.3.31 Fuser Latching Handle (L)(1) Remove the latching handle spring 1.(2) Unscrew the screw 2 to detach the fuse

58 / 21312.3.32 Belt Motor Assy(1) Remove the fuser latching handle (R) (see section 2.3.33).(2) Remove the two screws 1

59 / 3122.3.33 Fuser Latching Handle (R)(1) Remove the printer unit chassis (see section 2.3.25).(2) Remove the E ring 1.(

6 / MM MMMMMMLED HeadCentronics I/FUSB I/F2 ⋅ Option SlotsJunction BoardPulse MotorEngine ControlLow VoltagePower Unit

60 / 12112.3.34 Main Motor Assy(1) Remove the belt motor Assy (see section 2.3.32).(2) Remove all the connectors.(3) Remov

61 / 11253462.3.35 Main Feeder Drive Motor(1) Remove the two screws 1 to detach the main feeder drive motor 2.(2) Unscrew

62 / 432112.3.36 Contact Assy/ Left Plate Assy(1) Remove the printer unit chassis (see section 2.3.25).(2) Remove the fou

63 / 41425432.3.37 Low Voltage Power Supply(1) Remove the printer unit chassis (see section 2.3.25).(2) Unhook the connect

64 / 22132.3.38 High voltage power supply(1) Remove the contact Assy (see section 2.3.36).(2) Unhook the connector of the

65 / 1111233542.3.39 Main Feed Assy(1) Remove the printer unit chassis (see section 2.3.25).(2) Remove the low voltage pow

66 / 1188093674522.3.40 Cassette/ Left Guide Assy(1) Remove the printer unit chassis (see section 2.3.25).(2) Remove the m

67 / 1HG0BA3AFE67245981CD2.3.41 Cassette/ Right Guide Assy(1) Remove the printer unit chassis (see section 2.3.25).(2) Rem

68 / 31222.3.42 Fuser Unit(1) Open the top cover 1.(2) Push the right and left fuser levers (blue) 2 in the arrow directio

69 / 12432.3.43 Belt Unit(1) Open the top cover 1.(2) Remove the I/D unit.(3) Push the lever (blue) 2 in the arrow directi

7 / 1.2 Printer ConfigurationThe inside of the printers is composed of the followings:• Electrophotographic Processor

70 / 1LatchLatch2.3.44 Duplex Unit(1) Remove the cassette Assy, the front cover Assy and the front cover inner baffle.(2)

71 / 1132112.3.45 Guide Rails (L) and (R)(1) Remove the duplex unit (see section 2.3.44).(2) Remove the six screws 1 to de

72 / 2.3.46 Duplex Transport Assembly(1) Turn over the duplex transport Assy.(2) Unscrew the three screws 1 and five screw

73 / ABDCABCDEEFGGFDuplex transport sensor ⋅ 22322V4FDELMNKJYZTSaf5gcb]\[5X9867VUWe_QIPO0ABCHGRd1Idle roller springDuplex

74 / 2.3.47 CU Assy(1) Pulling out Controller Board1. Undo the two screws 1.2. Pull the controller board 2 out.3. Place th

75 / (3) Demounting TIG Board1. Remove the three screws 6 and screw 7 to detach the fan bracket 8.2. Remove the screw 9 an

76 / 3. ADJUSTMENTThis device is adjusted by key input from the operator panel.Other than the general menu, this device sup

77 / Table 3-0 (2/2) Maintenance Menu display TableItem(1st Line)Value(2nd Line)FunctionsThe details depend on Network.

78 / Maintenance MenuCategoryMAINTENANCE MENUItem(1st Line)EEPROM resetSAVE MENU Save menu settingRESTORE MENU Return to sa

79 / 3.1.2 Engine maintenance modeThree modes from Level 1 to Level 3 are in the engine maintenance mode. Level 1 is a mode

1.3 Supplies and ConsumablesProduct Code Description Quantity Estimated Yield CommentsAR-C20TBU Black Toner Cartridge 110,000 Images/Car

80 / 2. Press the 22222 and 66666 keys until the SCAN number that corresponds to the unit subject to thefollowing test list

81 / Paper emptysensorOHP sensorHeat/Humidity sensorCover up switchPaper weightsensorDuplex printrear sensorK toner sensorY

82 / SCANROWSWITCH SCAN 00SWITCH SCAN 01SWITCH SCAN 02SWITCH SCAN 03SWITCH SCAN 04SWITCH SCAN 05SWITCH SCAN 06SWITCH SCAN 0

83 / Table 3-2 Paper Size Detection - Paper /Bit Correspondence Table2HLLLLLL—L———L———1HLHLLLH—H———H———PaperNo cassetteLet

84 / 3.1.2.4 Motor clutch testThis self-diagnostic routine is used to test the motor and clutch.1. Press the 11111 and 5555

85 / ID motor (K)Resist motorResist clutchCassette 1 hopping motorCassette 2 clutchCassette 2 motorCassette 3 clutchCassett

86 / 3.1.2.5 Test printThis self-diagnostic routine is used to print the test patterns in the PU. The other test patterns a

87 / 4. Test print will be executed under the values set in Steps 2 and 3 by pressing the 33333 key when[PRINT EXECUTE] is

88 / Pattern 5 Pattern 6Pattern 7

89 / P: No. of test print pages (unit: page)U: Temperature of top heater [Set value] (unit: Celsius)L: Temperature of botto

9 / Option ConfigurationThe followings are available as options on the ARC200P.(1) 2nd Tray/ 3rd Tray (AR-C20PFU)(2)

90 / 3.1.2.6 Initializing NVMThis self-diagnosis is used for initializing non-volatile memory.1. Press the 11111 and 55555

91 / 3.1.2.7 Displaying the consumables counterThis self-diagnosis is used for displaying the consumed status of consumable

92 / 3.1.2.9 Panel display detailsPanel displayPanel DisplayBLANCE ERRORBELT LIFE OVERBELT REFLECTION ERRORBELT UNIT FUSE

93 / Panel DisplayDRIVE MOTOR OVER HEATDUPLEX I/F ERRORDUPLEX TYPE MISMATCHDUPLEX UNIT OPENENGINE BOARD FAN MOTOR ERRORENG

94 / Panel DisplayJAM TRANSPORTJOB OFFSET HOME ERRORLED HEAD OVER HEATLIFT ERROR TRAY1LIFT ERROR TRAY2LIFT ERROR TRAY3LIFT

95 / Panel DisplayPAPER NEAR END TRAY4PAPER NEAR END TRAY5PAPER PILE OUT OF TRAYPAPER SIZE ERRORPOWER SUPPLY FAN MOTOR ERR

96 / Panel DisplayCYAN REGISTRATION OUT RIGHTCYAN SENSOR ERROR LEFTCYAN SENSOR ERROR RIGHTCYAN TONER EMPTYCYAN TONER LOWCY

97 / 3.1.3 Various print jobs with single printer unit attached with a controllerMenu map printPrints program version, con

98 / 3.2 Adjustment After Replacing PartsThe following describes the adjustments that are required after each part replace

99 / 3.2.3 Replacing EEPROM after replacing the TIG boardWhen replacing the TIG board, remove EEPROM from the board used b

More documents for Copiers Sharp AR-C240P

(32 pages)

(32 pages)

Comments to this Manuals